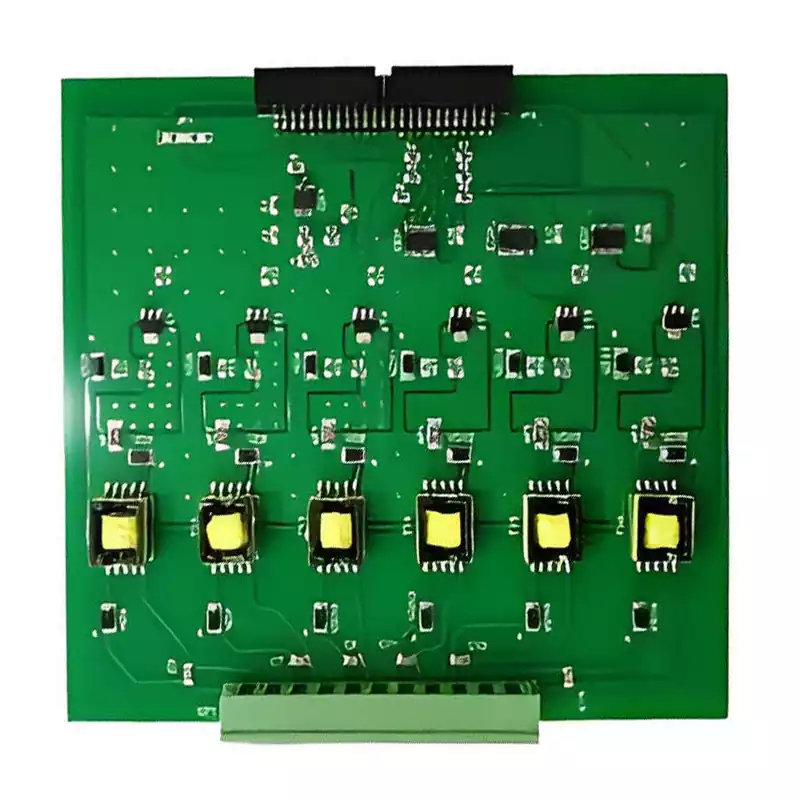

What is pcba? PCBA (PCB Assembly) constitutes a vital stage in electronic circuit design. It extends beyond the mere printed circuit board (PCB), involving the mounting of electronic components—such as surface-mount technology (SMT) and dual in-line package (DIP) components—onto the PCB substrate. Through processes including soldering, these components are integrated to form a complete circuit system.

PCB assembly finds extensive application across diverse electronic products, including televisions, computers, mobile phones, automotive electronics, and medical equipment. It serves as the indispensable core component for electrical connections and signal transmission within these devices.

The role of PCBA within electronic manufacturing is paramount. It constitutes the core assembly for diverse electronic products, including mobile phones, computers, and televisions. PCBA is responsible for interconnecting individual electronic components, enabling the entire electronic product to function correctly. Without PCBA, effective communication and collaboration between components would be impossible, rendering electronic products inoperable.

PCB assembly also enhances the performance of electronic products. During the manufacturing process, different electronic components can be selected according to specific requirements to achieve improved product performance. For instance, choosing high-performance processors and memory components can increase a computer’s processing speed and storage capacity; opting for high-resolution displays and premium audio chips can elevate a mobile phone’s visual and audio quality. Thus, PCBA plays a vital role in enhancing electronic product performance.

PCBA also contributes to reducing the size and weight of electronic products. With technological advancement, demands for portability and lightweight design in electronics continue to rise. PCBA serves as a key means to achieve this objective. Through precise manufacturing techniques, numerous electronic components can be densely integrated onto a compact circuit board, thereby diminishing the product’s dimensions and mass to meet consumer expectations for portability.

PCBA also simplifies the manufacturing process for electronic products. Compared to individually connecting each electronic component, PCBA pre-connects these components to the circuit board, forming a standardised modular structure. This streamlines the manufacturing process, significantly enhancing production efficiency and product quality. Simultaneously, modular design makes the production process more controllable, facilitating quality management and maintenance.

The entire production process for pcb assembly:

Blank board feeding (automatic board feeder)

The initial stage of PCB assembly involves arranging blank circuit boards neatly on a rack. Subsequently, the automatic board feeder conveys these boards one by one via a conveyor belt to the printing equipment on the SMT production line.

Solder paste application (solder paste printer)

Upon entering the SMT production line, PCB circuit boards undergo solder paste printing. Solder paste is precisely applied to the pads on the PCB designated for component soldering. This paste melts during the subsequent high-temperature reflow soldering process, firmly bonding electronic components to the circuit board.

Solder Paste Inspection (SPI)

The quality of solder paste printing—such as excessive or insufficient paste volume, and appropriate paste viscosity—directly impacts the reliability of subsequent component soldering. Consequently, some SMT factories employ optical inspection equipment immediately after solder paste printing to verify print quality and ensure consistent product standards. Boards exhibiting printing defects are typically scrapped, re-printed after solder paste removal, or manually corrected to eliminate excess paste.

High-Speed Placement (High-Speed Placement Machine)

High-speed placement machines are responsible for rapidly and precisely mounting small electronic components, such as miniature resistors, capacitors, and inductors in sizes like 0201 and 0402, onto circuit boards. These minute parts are lightly adhered and secured by the solder paste freshly printed onto the board. High-speed pick-and-place machines demonstrate exceptional efficiency when handling these diminutive components, ensuring they remain securely positioned for subsequent processing stages. However, they are unsuitable for larger electronic components, as their use would significantly impede overall production velocity.

General-purpose placement (Universal/Multi-functional pick-and-place machine)

Universal placement machines are primarily employed for mounting larger electronic components such as BGAs, ICs, connectors, and SOPs. These components demand exceptionally high placement precision, necessitating camera-based position verification prior to placement to ensure accurate alignment. Due to this requirement for precise alignment, their placement speed is comparatively slower. Depending on component size, packaging formats may include tape reels, trays, or tubes. Should components in tray or tube packaging be required, SMT equipment necessitates additional feeding apparatus. To facilitate pick-up by the placement machine’s nozzle, all electronic components typically feature a flat surface on their top. For irregularly shaped components lacking such a surface, customised nozzles may be required, or flat adhesive tape may be affixed to the component, or caps with a flat surface may be employed.

Reflow Soldering (Reflow Oven)

The reflow soldering process melts solder paste through heating, forming solder joints between component leads and the circuit board. Soldering quality is directly influenced by the oven’s temperature ramp-up and ramp-down profiles. Typically, reflow ovens incorporate preheat, wetting, reflow, and cooling zones to achieve optimal results. The maximum oven temperature should not exceed 250°C to prevent deformation or melting of components unable to withstand such heat.

Automated Optical Inspection (AOI)

Not all SMT production lines are equipped with automated optical inspection (AOI) machines. The primary purpose of AOI is to detect issues such as tombstoning, sideways placement, missing components, misalignment, bridging, or solder voids. However, AOI cannot assess solder quality beneath components (e.g., cold solder joints), BGA solder ball conditions, or the electrical characteristics of components themselves—such as resistance, capacitance, or inductance values. Consequently, AOI cannot yet fully replace In-Circuit Testing (ICT). Relying solely on AOI to substitute ICT still presents certain risks to product quality.

Final Visual Inspection

Regardless of AOI implementation, most SMT production lines incorporate a visual inspection zone. Its primary purpose is to identify any defective boards after assembly completion. The introduction of AOI can reduce the number of visual inspectors required, as manual checks remain necessary for details undetectable by AOI.

Circuit Board Open/Short Circuit Testing (ICT)

The primary purpose of implementing ICT (In-Circuit Testing) is to test whether components and circuits on the board exhibit open circuits or short circuits. Additionally, ICT can measure fundamental characteristics of most components—such as resistance, capacitance, and inductance values—to determine whether these components have suffered functional impairment, misplacement, or omission following high-temperature reflow soldering.

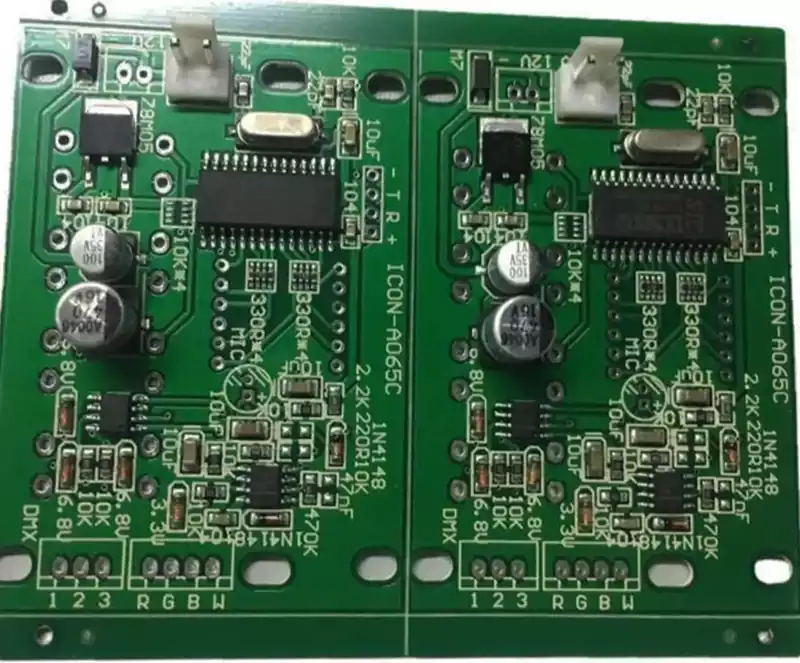

Panel Cutting

To enhance SMT production efficiency, pcb circuit boards are typically designed as panelised assemblies, such as two-in-one or four-in-one boards. Once all assembly operations are complete, these panels must be cut into individual single boards. Even single-board designs occasionally require trimming of excess board edges.

PCB assembly constitutes the indispensable core of electronic products. By precisely integrating electronic components onto PCBs, it forms fully functional circuit systems. PCBA not only underpins the normal operation of diverse electronic devices—such as mobile phones, computers, and televisions—but also serves as the key to enhancing product performance, reducing size and weight, and simplifying manufacturing processes.